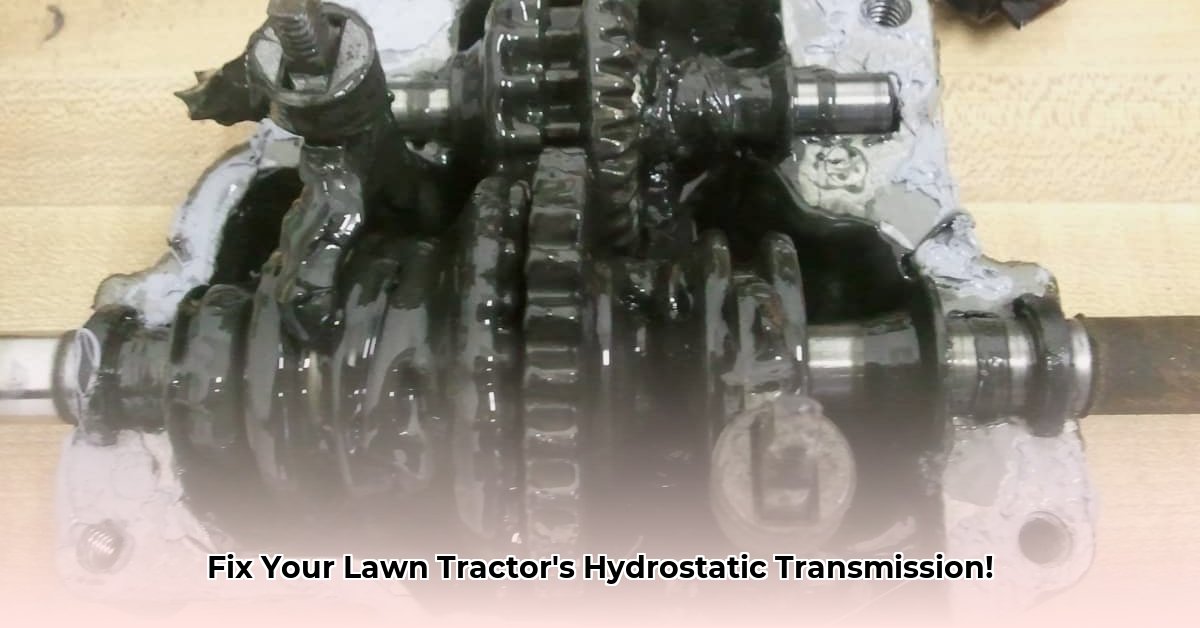

Understanding Your Hydrostatic Transmission

Your lawn tractor's hydrostatic transmission uses hydraulic fluid (a specialized fluid similar to brake fluid) to power the wheels. Unlike a standard gear-based transmission, it uses fluid pressure to control speed and direction, providing smooth operation and easy speed adjustments. However, this complex system has several potential failure points. For more troubleshooting tips, check out this helpful resource: Bad Boy Tractor Problems.

Common Hydrostatic Transmission Problems & Symptoms

Several warning signs indicate trouble with your hydrostatic transmission. Is your tractor sluggish? Does it whine, groan, or make unusual noises? Is there a fluid leak? Or is it completely unresponsive? Each symptom points to a potential problem, and ignoring these early warning signs can lead to more expensive repairs down the road. Don't wait until it's completely broken!

Step-by-Step Troubleshooting Guide

Let's diagnose and fix the problem! Follow these steps to pinpoint the issue:

1. Check the Fluid Level: Low fluid is the most common problem. Consult your owner's manual to locate the fluid level dipstick and determine the correct capacity. If low, add the correct type of hydraulic fluid specified in your manual. Using the wrong fluid can cause significant damage.

2. Investigate Leaks: Carefully inspect all hydraulic lines, fittings, and the transmission housing for leaks. Even a small leak can gradually drain the fluid, impacting performance. A simple visual inspection can save you time and money.

3. Examine the Fluid Condition: Check the fluid's color and consistency. Clean and appropriately colored fluid is good. Dark, murky, or burnt-smelling fluid suggests contamination, requiring a complete fluid and filter change.

4. Listen for Unusual Noises: Grinding, whining, or knocking sounds often indicate worn internal components. These usually require professional repair due to the complexity of the internal mechanisms.

5. Test Drive and Observe: After addressing any fluid issues, operate the tractor to assess any changes in performance. This helps determine if the problem is resolved or if further troubleshooting is needed. This step provides valuable feedback.

6. Bleed the System (If Necessary): Air bubbles in the hydraulic system can severely impact performance. Bleeding the system might be necessary. Your owner's manual may provide specific instructions. If not, seek professional help as this procedure can be tricky.

7. Identify Worn Parts: Persistent problems suggest worn seals, gaskets, pump, or motor issues. These often require professional diagnosis and repair given the specialized tools and expertise needed.

Preventative Maintenance: Proactive Care

Regular maintenance significantly reduces the likelihood of serious transmission problems.

- Regular Fluid Changes: Change the transmission fluid as recommended by the manufacturer (check your owner's manual). Don't underestimate the importance of regular fluid changes.

- Filter Replacement: Replace the hydraulic filter with every fluid change. This removes harmful particles and keeps the system clean.

- Visual Inspections: Regularly inspect for leaks, loose connections, and anything unusual. Catch small problems before they become large, costly issues.

When to Call a Professional

Some problems require specialized tools and expertise. Don't attempt repairs beyond your capabilities. A qualified mechanic can accurately diagnose complex issues like pump or motor failure, ensuring a proper repair and extending your tractor's lifespan.

Common Problems, Causes, and Solutions

| Problem | Possible Cause(s) | Solution |

|---|---|---|

| Sluggish Performance | Low fluid, dirty fluid, air bubbles, worn parts | Check/add fluid, replace filter, bleed system, professional repair |

| Fluid Leaks | Worn seals, gaskets, damaged lines | Replace seals/gaskets, repair/replace lines |

| Unusual Noises | Worn bearings, internal component wear | Professional repair often needed |

| Total Transmission Failure | Major internal failure, pump/motor failure | Professional diagnosis and repair are essential |

Addressing minor problems promptly prevents major repairs. Regular maintenance and prompt attention to warning signs help keep your lawn tractor running smoothly for years to come. Investing time in preventative care pays off!